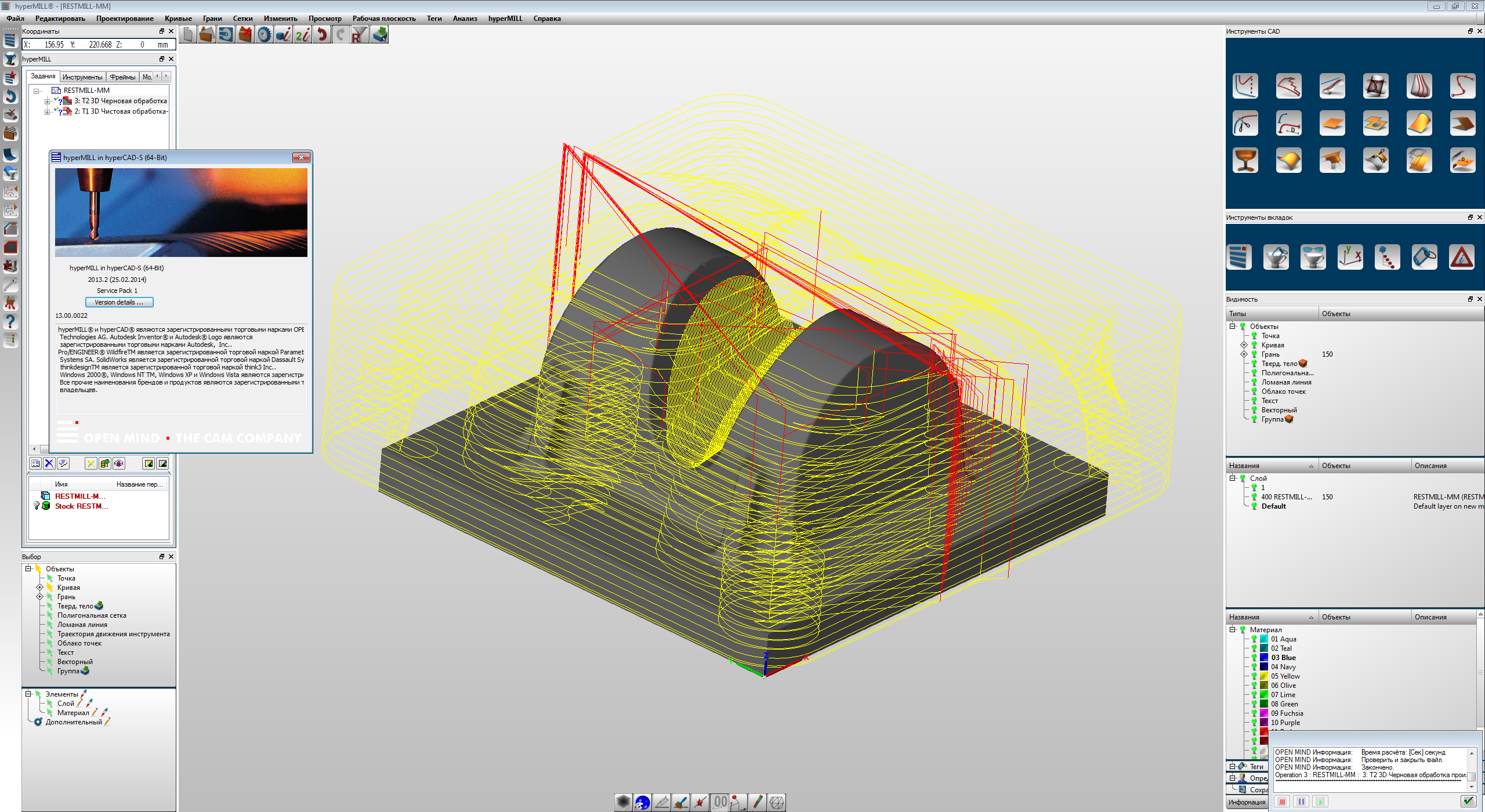

“Virtual Surfaces” allows open areas of a channel to be closed or surfaces at the beginning to be correspondingly extended for the calculation of the tool paths. Programming is simplified compared to simultaneous machining (without collision avoidance and slope angle).

The finishing strategy has been fundamentally enhanced and now offers new and improved functions.Ī new calculation method ensures that the start and end of machining can also be optimized for this tilt strategy with woodruff cutters.

Further improvements make this strategy the benchmark for blow mold machining.

0 kommentar(er)

0 kommentar(er)